Part # B841

Warranty 1 Year

Manufacturer Code B2841V1

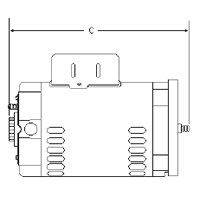

Dimensions 14" L x 6.5" W x 6.5" D

Century Centurion (Magnetek) replacement motors for Pentair WhisperFlo, energy efficient, full rated pumps. Specifications: HP = 1, RPM = 3450, Voltage = 115/208-230, Amps = 14.8/7.8-7.4, Service Factor = 1.65, Frame = 56Y, Shaft = Threaded.

Note: NOT California or New York Title 20 Compliant.

California and New York Title 20 Compliant Option:

What is Service Factor?

Reply

Service Factor(SF) is a multiplier that when multiplied by the horsepower of the motor indicates the total permissible horsepower loading that may be carried when the motor is operating at rated voltage and frequency. The most important thing to remember when replacing a motor is that the replacement motor's horsepower times its service factor must be equal to or greater than the original motor's horsepower times its service factor. The Service Factor rating can be found on the motor label. See Step 4 of our How to Read a Pool Motor Label guide.

Reply

Why do I need to purchase a new shaft seal?

Reply

We strongly recommend replacing the shaft seal. The purpose of a shaft seal is to prevent water from running down the shaft of the motor and into the motor housing. Water will damage the bearings and cause the motor to fail. A new shaft seal should be installed whenever a motor is replaced. The motor manufacturer can deny the warranty if the motor fails to due to water damage from a faulty shaft seal. To find your shaft seal you will need to visit our Pool Pump Parts Page or the Spa Pump Parts Page and select your make and model.

Reply

Why should I purchase a Tune Up Kit?

Reply

A Tune Up Kit includes all of the essential replacement seals and gaskets for the pump. The seals and gaskets should be replaced when installing a new motor on your pump. New seals will prevent the pump from leaking water or losing the prime. A Tune Up Kit will protect your motor and ensure that the pump is working efficiently.

Reply

I'm trying to replace the motor on my pool pump but all these numbers and abbreviations on the motor label are really confusing me. What do they mean?

Reply

Replacing a pool pump motor is not as difficult as it seems. You can try looking here. If you need help figuring out what the information on your label means. If you are still having difficulty figuring it out you can call us at our toll free number or you can send us a photo of your motor label here.

Reply

I just finished replacing the shaft seal on my booster pump. As soon as I turned the pump on water was leaking from the shaft seal. Is it defective or am I doing something wrong?

Reply

Depending on the model, the installation of a booster pump shaft seal can be slightly different than a pool pump shaft seal. Some booster pump and pool pump shaft seals require that a silicone sealant be used on the outer areas of the metal seat of the shaft seal. The seal will need to be lightly hammered into the body of the pump. You can use a 1 inch PVC coupling or a piece of 1 1/4 inch PVC pipe and a rubber mallet. This procedure will apply to any pool pump or booster pump using a >PS-1000 style shaft seal.

Reply

Less than 1 hr

Screwdriver, Socket Set, Adjustable Wrench

1 0

I was discouraged after being told our pump was not working while trying to open the pool for the season. I was told a replacement would be $700.00 plus. I search the internet and found it here at INYOPools for less than $400. I watched a few videos on pump replacement and decided to take it on. I made sure the electric was off and no longer hot from the panel. There were two sets of bolts, one for the pump to the impeller housing and one set for the housing to the filter housing. I used a 9/16th inch socket to remove the bolts holding the housing to the filter housing. Once this was removed, it was easier to remove the bolts holding the pump to the impeller housing, with the same 9/16th inch socket. Once both were free and separated, I used a straight screwdriver to remove the screw holding the impeller on the motor, while holding the bolt on the back of the motor still with an adjustable wrench. Once this was apart, I had access to the pump seals, which were easily pulled off. I was able to replace the lower seal with the new part, but the upper seal was still in great shape and I left it on. Once I was ready to reassemble, the steps were very easy in reverse. The only addition was using a vasoline around the edges of the gaskets that were around the impeller as well as around the housing that connected to the filter housing. This just allowed a better seal in hopes that I would not have to replace the gasket. I had a 240V connection, so both black wires were connected and then the ground. I also had a bonding wire that connected to the back of the motor as well. Once these connections were made, I cleaned up everything around the motor and turned the power back on. I was excited to hear the motor come on and then after priming the pump to see all of the outlets start moving water. It took about 1 hour and was super easy to do.

1 to 2 hrs

Screwdriver, Electrical multimeter

Long story short, the house we bought had a noisy bearing. I mean LOUD. Our neighbors complained. Overwinter, it seized. Upon recognizing the equipment failure, I ordered these parts intending to replace the bearing and seals, but instead procrastinated and lost these when the time came. Ordering more, will review when complete 👍🏻

1 to 2 hrs

Screwdriver, Nut Drivers, Socket Set, Wrench Set, Impact wrench, strap wrench

1 0

I first turned off all power to the pool equipment. Then I disassembled the challenger pump and the electrical connections to the motor. This allowed me to take the motor with pump backing plate and impeller to my workbench for further disassembly.

Don’t forget the screw holding the impeller to the motor shaft is turned clockwise to loosen. A strap wrench makes impeller removal easy turning it counterclockwise to remove from the motor shaft. The hardest part was loosening the bolts holding the old motor to the pump backing plate. An impact wrench was required but after copious lubrication I got them off. I cleaned the bolts with a wire brush before reassembly. Then replaced the backing plate portion of the seal and bolted on the new motor.

Then reassembled the pump backing plate and motor with new O-rings and the impeller side of the new seal. Went back outside to complete the pump reassembly and connected the electrical. Primed the pump and turned electrical power back on and started it up! Success. No more noisy pump motor.

1 to 2 hrs

Screwdriver, Socket Set, Circuit tester to test to make sure no wires are hot

3 0

1. Ensure power is cut off to unit at both panels

2. Disconnect power lead to old motor

3. Remove bolts that connect back plate with motor still attached and pull from the pump housing

4. Once these bolts are removed you can lift the entire unit (motor and back plate) out and then disassemble motor (4 bolts I think) from motor to back plate.

5. Remove the diffuser which allows access to impeller and remove 1 stainless steel bolt in center

6. Now you can remove the impeller that will allow access to motor mechanical shaft seal 7) With back place off and impeller removed replace new seals and reverse order

2 to 4 hrs

Screwdriver, Nut Drivers, Pliers, Socket Set, Wrench Set, Adjustable Wrench

6 0

1 to 2 hrs

Screwdriver, Socket Set, Wrench Set, Adjustable Wrench

2 1

I removed the old pool motor, housing, and impeller. I matched the specifications of existing motor and ordered a new one from INYO pools. After receiving, I went to a local pool store to buy the shaft seal as I forgot to order. Once I had that, wired everything back up, attached back to my filter and flipped on the power. Worked perfectly.

1 to 2 hrs

Screwdriver, Socket Set, Wrench Set, Adjustable Wrench

3 1

ordered on line and got a how to video that was very helpful the job itself was not to bad but I did not watch the video right away and ended up messing the seal up on the first try, but after watching the video, figured out what I messed up and fixed it in no time

The Most Recent Reviews

(5 out of 5 stars) Great customer service. Perfect part. easy to replace.

Reviewed By: Inyo Customer ()

Perfect replacement motor. the customer service rep helped me find the right part and very quickly as well. He was very knowledgeable and was super helpful in all my questions. he even knew the quirks of the web site and showed me how to make sure i find the right parts on my own if needed next time.

Was this review helpful to you?

(3 out of 5 stars)

Reviewed By: Inyo Customer ()

Lasted only 6 years. Original equipment (Jandy Stealth SHPM 1.5) installed Mar 2013, Purchased this one ($199) to replace original motor on Feb 2018, replaced again on Jan 2024 (same motor for $282). Texas weather. Running pump daily 8-10 hours. Winter 6 hours. 14,000 gallons pool. No spa just a single waterfall and cleaner once a week. Let see how long the replacement last. It’s not as quiet as the original equipment.

Was this review helpful to you?

(1 out of 5 stars)

Reviewed By: Inyo Customer ()

Bearings went out after 2 years.

Was this review helpful to you?

(5 out of 5 stars) Flawless Order Delivery

Reviewed By: Inyo Customer ()

Quickest and most aggravation free order for pool parts I've ever placed from a pool supply company. Received the parts in record time and will not consider ordering from another supplier going forward - great experience!

Was this review helpful to you?

(5 out of 5 stars) They picked the right replacement!

Reviewed By: Inyo Customer ()

Part came complete, works as intended! Don’t forget to replace your gaskets and seals while you’ve got your pump apart!

Was this review helpful to you?

(5 out of 5 stars)

Reviewed By: Inyo Customer ()

Customer was waiting for the new motor because she thought her pool was going to get green, motor took less time that I expected, I replace it on 45 minutes and she like how quiet the moto is, and another customer happy.

Was this review helpful to you?

(4 out of 5 stars) Doesn't last very long

Reviewed By: Inyo Customer ()

Doesn't last very long.

Was this review helpful to you?

(5 out of 5 stars) Definitely replace your own pump motor

Reviewed By: Inyo Customer ()

This is the second motor like this that I have purchased. I think it is a good value for the money and is quiet and energy efficient. Replacement is quite easy so I would never pay to have this job done by a pool contractor.

Was this review helpful to you?

(5 out of 5 stars) Great service

Reviewed By: Inyo Customer ()

Great service, exactly what I needed and works great.

Was this review helpful to you?

1 0

(5 out of 5 stars)

Reviewed By: Inyo Customer ()

I have to say I love the new motor. It is so quite and has plenty of power.

Was this review helpful to you?

0 1

(5 out of 5 stars)

Reviewed By: Inyo Customer ()

Love it

Was this review helpful to you?

1 0

(5 out of 5 stars) Excellent pool pump replacement motor

Reviewed By: Inyo Customer ()

Motor shipped quick, called with a couple of question, very helpful and professional. Heavy duty motor - would recommend!!

Was this review helpful to you?

(5 out of 5 stars) 1 HP Motor EE - Full Rate (B2841)

Reviewed By: William T. from Baltimore, MD ()

Fair price. Fast shipping. Good quality product.

Was this review helpful to you?

(5 out of 5 stars) Great pump

Reviewed By: pbueno ()

Pros: Quiet

Cons: None

Delivered as promised. Quiet and an easy install.

Was this review helpful to you?

(5 out of 5 stars) Great service

Reviewed By: Daniel D. from Carefree, Arizona ()

Pros: Great service

Cons: None

No hassle replacement of defective motor.

Was this review helpful to you?

(5 out of 5 stars) The 1 HP motor fit perfectly, as ordered.

Reviewed By: Marcus O. from Spokane WA ()

At first I was not sure if I would be able to order the exact 1 HP motor the first time, but the on-site information was detailed enough, that when I received the Motor it fit perfectly!

Was this review helpful to you?

(4 out of 5 stars) Pump and motor fit right in replacing our old pump which was exceptionally loud and obnoxious. Easily assembeled. I did use online videos to see how to assmeble. I also had to ask INYO for guidance on

Reviewed By: Michael J. from Macedonia, OH ()

Pros: Tech information always and quickly provided by INYO at request

Cons: No clear instructions provided with motor.

Pump and motor fit right I, replacing our old pump which was exceptionally loud and obnoxious. Easily assembled. I did use online videos to see how to remove and install. I also had to ask INYO for guidance on reversing the pump rotation when it first starded as is would over heat and shutdown. They sent me a simple explantion and fix by email. After that the pump worked like a charm.

Was this review helpful to you?

(5 out of 5 stars) shipped fast

Reviewed By: John F. ()

exact fit and was shipped very fast. I would recommend this company for pool supplies.

Was this review helpful to you?

(5 out of 5 stars) Value Replacement Pump

Reviewed By: Jon M. from Little Elm, TX ()

Pros: Quiet

Solid value and quality. Staff was an immense help with guidance and installation assistance of this unit over the original seven year old pump. Pump is cool and quiet and works just as good if not better than the original.

Was this review helpful to you?

(5 out of 5 stars) Ooutstanding Pool Pump Motor

Reviewed By: Lucilo E. from Yuma, Az ()

Pros: How Quit the motor is.

Cons: Wiring diogram and seal kit for those not mechanicly encline.

Our old pool pump motor sounded like it was going to self destruct. I ordered the new motor and it arrived in 5 days, even with the free ground shipping. It was easy to install,3 wires and its done. The pool pump is right outside our bedroom, and we cant hear the motor running. We are so happy with this product, and I'm sure our Nabors are too.

Was this review helpful to you?

(5 out of 5 stars) replacement pump

Reviewed By: Brett F. ()

well done, very knowledgeable online chat, part was exactly what I needed, came quickly, figured everything out with simple chat

Was this review helpful to you?

(5 out of 5 stars) Excellent Pool Pump Motor

Reviewed By: lakeside_tony from Cumming, GA ()

Pros: Very quiet, great price

Cons: None

I received this pump motor very quickly, and the INYO website made it real easy to find exactly what I needed. I did call to confirm the replacement and staff were very helpful. The motor is extremely quiet and was a breeze to setup/install. My order confirmation email even had links to several videos relevant to installation. Can't go wrong with this motor or with INYO Pools. Thanks Again !

Was this review helpful to you?

(5 out of 5 stars) 1 HP Motor EE - Full Rate (B2841)

Reviewed By: kaoskontrol from Gilbert AZ ()

Pros: Direct Fit, Amazingly Quiet, Energy Efficient

Cons: None

This replaced my 13 year old AO Smith 1 hp motor (part # 7-177475-20) that finally failed. The motor went in without any hitches and runs quieter than the original. Shipping was fast and the price couldn't be beat.. Customer support was excellent as they were able to assure me that this motor is a direct replacement to the original as well as the correct gasket/seal kit needed. Local dealers wanted over three times this amount to install it. Thanks InyoPools!

Was this review helpful to you?

(5 out of 5 stars)

Reviewed By: Chris Z. ()

Super quiet, direct fit. I don't remember my original motor ever being this quiet.

Was this review helpful to you?

(5 out of 5 stars) pool poump

Reviewed By: Tim S. from temecula, CA ()

good,quiet pump

Was this review helpful to you?

(4 out of 5 stars) WhisperFlo EE - Performs as Specified

Reviewed By: Richard S. from Livermore, CA ()

Pros: quiet

Cons: none

Easy install, performs as specified.

Was this review helpful to you?

(5 out of 5 stars) The whisper flow motor fit perfect!

Reviewed By: Dan R. from St. Charles, MO ()

Pros: good price in stock and it was the right part the first time.

Cons: None

They reminded me to get the extra little seal kit which is required. I was very happy with the product and their service. The price was the best price I could find after shopping it to death! Good product, it fit, I am not mechanical but found a you tube video that was specific to my pump so it made it really esy to reassemble. I also used my cell phone to take pics where the wires were located on the old pump before disassembly. I would order from this company again.

Was this review helpful to you?

(5 out of 5 stars) Good quiet motor

Reviewed By: Phantom from South Euclid, OH ()

Pros: quiet, cheap, fits outdated models

Motor is extremely quiet, runs good and fits pentair superflow pumps.

Was this review helpful to you?

(4 out of 5 stars) single speed motor in a two speed world

Reviewed By: Ryan L. from Folsom, CA ()

Pros: Easy to wire with no worries of voltage backwardation

Cons: Hard to match up worn parts based on old naming

Excellent shipping time and price given the weight and distance. The install was a snap and the tech help was great.

Was this review helpful to you?

(5 out of 5 stars) great motor

Reviewed By: Amin D. from Anaheim, CA ()

Inyo had the best prices and I recieved my pump motor fairly quickly and installed it pretty easily. Runs so quiet! Thanks

Was this review helpful to you?

(5 out of 5 stars) Easy to install

Reviewed By: Bill M. from mount pleasant, SC ()

Cons: Instructions could have been better.

UPS delivered it at about 10AM and I had it installed by 2PM. 1st pump motor I ever installed.

Was this review helpful to you?

(5 out of 5 stars)

Reviewed By: Joe B. from La Mirada, CA ()

Simple, easy, cheap! perfect for my budget

Was this review helpful to you?

(5 out of 5 stars)

Reviewed By: Stacey S. from Greensboro, MD ()

Excellent Product

Was this review helpful to you?

2 0

(5 out of 5 stars) Replacement Pump Motor

Reviewed By: CWO4 John S. from Virginia Beach, VA ()

Pros: Great Tech Support, Low Price

My pump died slowly. I did not want to pay the $700+ to have someone remove and replace it. I wasn't sure which pump to get. I wrote down all of the pump specifications from the placard located on the side of the pump on an email to INYO Tech support. They emailed me a direct link to the correct replacement pump. The pump noise level was dramatically lower than the original was brand new! I misplaced the wiring diagram and they gave me excellent directions on proper placement of the wires. Outstanding support all the way around. I paid less than 1/3 of the repair price by doing it my self. It's not hard. I would definitely recommend this company to all of my pool owner friends in the future. Thank you so much INYO!!! Br/ John S.

Was this review helpful to you?

1 0

(5 out of 5 stars) Exact Replacement

Reviewed By: LenO from Great Falls, VA ()

Pros: Prompt and expert phone assistance.

Got it on time, right motor, easy replacement at lowest cost.

Was this review helpful to you?

1 0

(5 out of 5 stars) Pump Motor

Reviewed By: Andy from Bedford, TX ()

Pros: Great item and perfect fit

Cons: No cons

I'm glad I found Inyo Pool Products on the web. It was easy to find exactly the right product at the right price, and including shipping it was less than if I'd purchased the motor at a local pool store.

Was this review helpful to you?

2 0

(5 out of 5 stars)

Reviewed By: GREENHORNET from Arcadia, Fl. ()

Pros: quick ship, installed same day, runs great, no surprises

Cons: none

Was this review helpful to you?

3 0

(5 out of 5 stars) The replacement motor you want

Reviewed By: Jimbob from Raleigh, NC ()

Pros: Easy to install

Cons: none

I installed this motor on a five year old Pentair pump with failing bearings. It took me under an hour and I had never done it before. It's working great and is quieter than the pump was when it was new. You should replace the seal and use the kit they sell at INYO and you can replace some gaskets at the same time.

Was this review helpful to you?

(5 out of 5 stars) Pump motor

Reviewed By: G-dub from Greenville, NC ()

Pros: Very easy to replace

Exact replacement motor and saved cost of a new pump.

Was this review helpful to you?

44 6

(5 out of 5 stars) Pool Filter Motor

Reviewed By: DreamBigGoGreen from Bowie, Maryland ()

Pros: Customer service, shipping time, price and product

Cons: None that I can think of

Best of all is the wonderful customer service help provided by Inyopools. The product was here in the time specified and the price was considerably less than the 5 other companies I checked with first. The product was as specified and ordered and hasn't given me any problems to date. It was installed about a month ago.

Was this review helpful to you?