An important part of a new pool pump installation is the circuit wire used for the power source to motor connection. To make your pump run as efficiently as possible, your pump motor needs enough juice too. In this article, we’ll cover the basics of selecting the correct wire for your motor.

What to consider when picking the wire gauge?

Material

The one and only choice for a wire material for a pool pump is copper. Copper has a lower resistance than aluminum which is the other common wire choice. Copper’s low resistance lessens voltage drop.

Length of run

This refers to the length of wire needed to span from the power source (usually the circuit-breaker box) to the pool pump motor. The longer the wire, the thicker it needs to be. Remember that thin wire has a higher resistance causing higher voltage a drop which leads to an overheating motor

Pump Horsepower & Voltage

The higher the motor horsepower, the more electricity it requires. The voltage being supplied to the motor plays a factor because of the number of hot wires used for 115 and 230. A 115-volt circuit has only one hot wire carrying, meaning the amperage is carried solely through that wire. This means that the wire has to be thicker to avoid overheating. A 230-volt circuit has two hot wires carrying voltage, splitting the amperage draw evenly, allowing a smaller gauge to be used.

Wire Gauge Chart

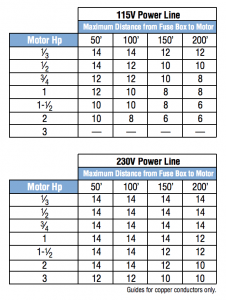

This wire gauge chart provided by A.O. Smith:

Why is wire gauge important?

For your pool motor to generate power (watts), it requires two things from your electrical source – amperage and voltage. The circuit bringing the amperage and voltage to your pump needs large enough wires to accommodate both of these elements for the motor to operate efficiently. The motor is shooting for its wattage goal, and can harm itself in trying to reach it.

P (Watts) = PF(Power Factor) × A (Amps) × V (Volts)

If the circuit wires are too narrow, the motor usually sacrifices voltage to overcome the bottleneck in the wire. The motor, in turn, draws more amperage so that it can meet its power demands. Unfortunately, the higher amps create more heat, stressing the motor and lowering its life expectancy.

Intex sand filter pump 0.75 HP – 110 amp – 120 v

125′ from box to pump – what wire should be used?

Going by this handy-dandy chart in the article, I would presume 10-gauge wire.

Hp pool filter pump. Run to breaker is 1+ ft. Im thinking 10 guage uf wire and a 15 or 20 amp breaker. Any suggestions. Thanks.

It would be necessary to know the motor HP, its voltage setting, and a clarification on the wire run. 1+ feet from the pump to breaker seems extremely short.

Typo. 100 feet

Ok, but you still haven’t addressed the voltage you’re using or the horsepower of the pump. I couldn’t tell you which breaker to use because I don’t have most of the information needed to make that call.

3/4 hp pump that i may upgrade to 1 1/2. I decided to use copper 10-2uf. 20 amp breaker dedicated to only the pump. Wire distance is less than 100 ft. I put the wire in 1″ pvc and buried it 12″. I should be good to go

Okie-Doke.

Have new Hayward pump system EC50 came with 14 gauge wire. County says it needs to be 12 gauge wire. Inspector came today and did not pass it. Is this correct?

It is different for every county; I suggest taking a look at the inspection requirements to determine what wire gauge you need. Or, follow the instruction of the inspector who is telling you to correct it. If you want it to pass inspection, I’d follow their guidelines.

The length of the run also affects the gauge of the wire. That is an important part of the equation you left out.

I’m also going through this right now…cable too long and incorrect gauge. My main question is why is the equipment sold with 14 gauge 48″ wire if 12 gauge 36″ wire is what is required?? I don’t think opening a brand new piece of equipment and jamming a wire 2x the size of the original inside is wise.

I just got denied yesterday same thing has to be 3feet and 12 awg I have a pantair dynamo and can’t seem to find a wire at all !! All the wire aren’t 12awg or they don’t list the awg !!! Have you had any lock on finding a wire if so where ???

Voltage drop doesnt apply to the load only the supply wiring.

Hayward often leaves a set of test wires that are not meant to be used. I do not understand why they leave them there. At least the newer Hayward VS. We have been trained and equipped to only use 12 gauge solid core wires.